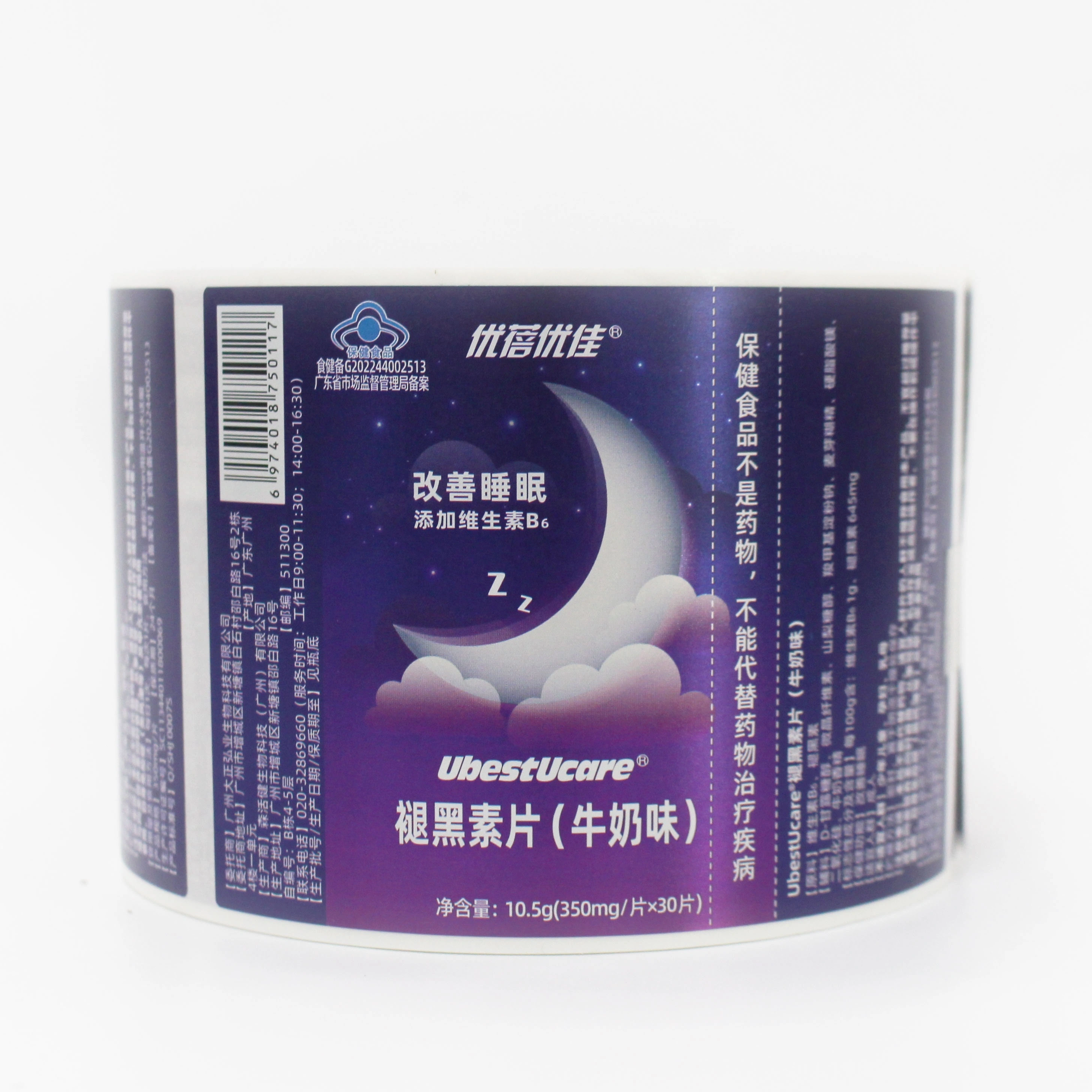

Glossy silver paper combined with reverse UV for healthcare label-1731918055518213

Shimmering Silver Packaging Enhancement

Glossy silver paper (usually referred to as paper coated with a metallic silver gloss) is a high-gloss paper material that has a shiny metallic effect. The reverse UV process is a printing technology that uses ultraviolet curing, usually on the basis of transparent or white ink, through the reverse printing technology to present details, so that the pattern and image on the surface of the metallic luster show a unique effect. The combination of the two is able to create a metallic sheen with fine patterns and unique visuals.

● Enhanced Packaging Solution

● Durable and Stylish Protection

● High-Quality Design

● Stylish and Protective Packaging

Product Display

Durable, vibrant, versatile film

Exquisite Elegance, Superior Quality

Reverse UV technology enables precise printing of patterns on the surface of glossy silver paper. The glossy silver paper itself is smooth and flat, and the reverse UV process guarantees very high quality pattern printing on its surface. Whether it is small text, complex patterns, or gradual color change, reverse UV can maintain very high accuracy, avoiding the phenomenon of color difference, blur or leakage in traditional printing.

◎ Durable and Water-Resistant

◎ Sleek and Professional Appearance

◎ High-Quality Print and Matte Finish

Material Introduction

Glossy silver paper has its own metallic luster, which can give the printed matter a gorgeous appearance. The reverse UV process uses reverse printing to make the pattern on the surface of the glossy silver paper transparent, translucent or other fine effects. When the two are combined, the silver luster is combined with the transparent pattern, which can present a very unique three-dimensional and hierarchical sense. The reverse UV presents a delicate pattern on the metallic gloss paper, making the pattern look like relief, enhancing the visual richness.

FAQ